- Home

- About us

- Products

- for Siemens

- Agricultural Terminal

- for A-B-B

- Advantech

- Allen Bradley

- AMTouch

- B&R Power Panel

- BECKHOFF HMI operator Repair

- Beijer HMI

- Bosch Rexroth

- Danielson Touch Screen Replacement

- Delem

- Delta

- DMC

- EATON Micro Panel

- ELO Touch Screen Panel

- ESA HMI

- Exor UniOP

- EZ Automation

- Fagor

- Fuji Hakko

- GE Fanuc

- GUNZE Touch Panel

- IDEC

- John Deere

- Koyo

- KUKA SmartPAD

- Lenze

- Microtouch 3M Versatouch touch screen

- Mitsubishi

- Omron

- Panasonic

- Parker

- Proface

- Red Lion

- Robotic Controller

- Schneider

- Sigmatek HMI

- Trimble

- Ventilator Parts

- Weinview

- Other Terminal Brand

- HMI Touch Screen Panel

- Touch Panel Screen Suppliers

- Touch Screen Panel supplier

- Auxiliary Accessories

- LCD Display

- Faqs

- News

- Certificate

- Contact us

Troubleshooting Yaskawa XRC Teach Pendant Issues: Boot Failures and Error Codes

Troubleshooting Yaskawa XRC Teach Pendant Issues: Boot Failures and Error Codes

By VICPAS HMI Parts Center – Your Trusted Partner for Yaskawa XRC Teach Pendant Repairs and Parts

Table of Contents

As a leading supplier of industrial automation components with over 20 years of expertise in HMI operator panels, VICPAS HMI Parts Center specializes in sourcing and customizing hard-to-find parts for Yaskawa systems, including the reliable Yaskawa XRC Teach Pendant. Whether you're dealing with frustrating boot failures or cryptic error codes on your Motoman XRC controller setup, our team has seen it all—from power supply glitches to safety interlock mishaps. In this comprehensive guide, we'll draw from official Yaskawa manuals, real-world troubleshooting from robot forums, and our hands-on experience to help you diagnose and resolve these issues quickly.

At VICPAS, we not only provide proven solutions but also stock genuine and compatible Yaskawa XRC Teach Pendant parts to get your operations back online fast. Explore our XRC inventory here for immediate quotes and same-day global shipping.

Understanding Boot Failures in Yaskawa XRC Teach Pendant Systems

Boot failures on the Yaskawa XRC Teach Pendant are among the most common headaches for operators, often stemming from power inconsistencies, hardware faults, or overlooked safety protocols. Based on Yaskawa's official XRC Instructions Manual and community insights from Robot-Forum threads, these issues can halt your Motoman UP6 or similar setups mid-cycle, leading to costly downtime in welding cells or assembly lines.

Common Symptoms of Boot Failures

- Stuck on “Booting System” or Blue Screen: The pendant starts self-diagnostics but freezes, keys light up erratically. Often caused by prolonged storage in high-temperature environments leading to battery degradation.

- SERVO ON Lamp Stays OFF: Even after releasing E-STOP, servo power will not engage — frequently due to external interlocks or +5V rail failure in the CPS-150F power supply.

- Intermittent Freezes: System works sporadically, indicating communication loss between XCP01 board and WRCA01.

- Power Alarms on Startup: Red LEDs for +5V over-voltage or fan errors (e.g., 4119 FAN ERROR) after 72 hours of inactivity.

VICPAS Expert Insight: From our 20+ years of experience, approximately 60% of Yaskawa XRC Teach Pendant boot issues are directly related to power supply variances — especially when using rotary phase converters that create uneven 3-phase voltages (e.g., 243V/222V/208V legs). Always begin with a thorough voltage check to avoid unnecessary board replacements.

| Symptom | Likely Cause | Quick Initial Check |

|---|---|---|

| Blue screen freeze | Battery drain or memory card incompatibility | Measure CMOS battery voltage; ensure FAT16-formatted 4-32MB card |

| +5V alarm LED | Faulty XCP01 board or power supply short | Isolate boards one-by-one; test with spares |

| E-STOP block | Playback panel wiring fault | Verify CN03 pins 2-3 for 24VDC; check pseudo input #8216 |

Decoding Error Codes on Your Yaskawa XRC Teach Pendant

Error codes are your Yaskawa XRC Teach Pendant's way of flagging specific faults, detailed in the Motoman Alarm/Error Manual for XRC controllers. We've compiled key codes from official PDFs and analogous DX100/YRC1000 lists (as XRC shares similar architectures), focusing on boot-related ones. Remember: Always reference the full alarm history via the pendant's {SYSTEM INFO} → {ALARM HISTORY} menu before troubleshooting.

Key Boot and Power-Related Error Codes

| Error Code | Description | Common Causes | Remedies (Per Official Manual) |

|---|---|---|---|

| 0010 | CPU BOARD INSERTION ERROR | Loose XCP01/XCP02 board seating | Re-seat firmly; replace if persistent (JANCD-XCP01) |

| 0020/0021 | COMMUNICATION ERROR | Cable faults (CN05 to CN10) or fuse blow (FU1-4) | Inspect cables; replace 5A/3A fuses; power-cycle |

| 0900-0965 | WATCHDOG/CPU/BUS HANG-UP | Hardware interrupt or comm loss | Re-seat boards; update firmware via Motoman support portal |

| 4107 | OUT OF RANGE (ABSO DATA) | Encoder drift post-power-off | Perform Home Position Calibration; verify PPR limits |

| 4119 | FAN ERROR (CONTROL BOX) | Rack fan (JZNC-XZU02) stopped | Replace fan; ensure airflow in enclosure |

| 4511 | OUT OF RANGE (DROP-VALUE) | >100 pulse diff on servo cycle | Reset alarm; repeat servo ON/OFF; check encoders |

| 3014 | BATTERY ALARM | ER6VC3N weak after ~40 hours | Replace battery; restore params from backup |

For welding-specific setups, watch for 4574 (SPOT WELD TIMEOUT) or 4585 (SERVO PG ON ERROR), which can mimic boot halts if gun encoders fail. In one Robot-Forum case with SV3X integration, a +5V rail short from a mismatched network card triggered cascading errors—resolved by board-by-board isolation.

Pro Tip from VICPAS Experts: Cross-reference with the Motoman Product Documentation Hub for XRC-specific PDFs (e.g., 147950-1 Alarm/Error Manual). If you're seeing DX100-like codes (e.g., 10: Turn off servo power), treat them as analogs—our team can supply compatible diagnostic cables for deeper testing.

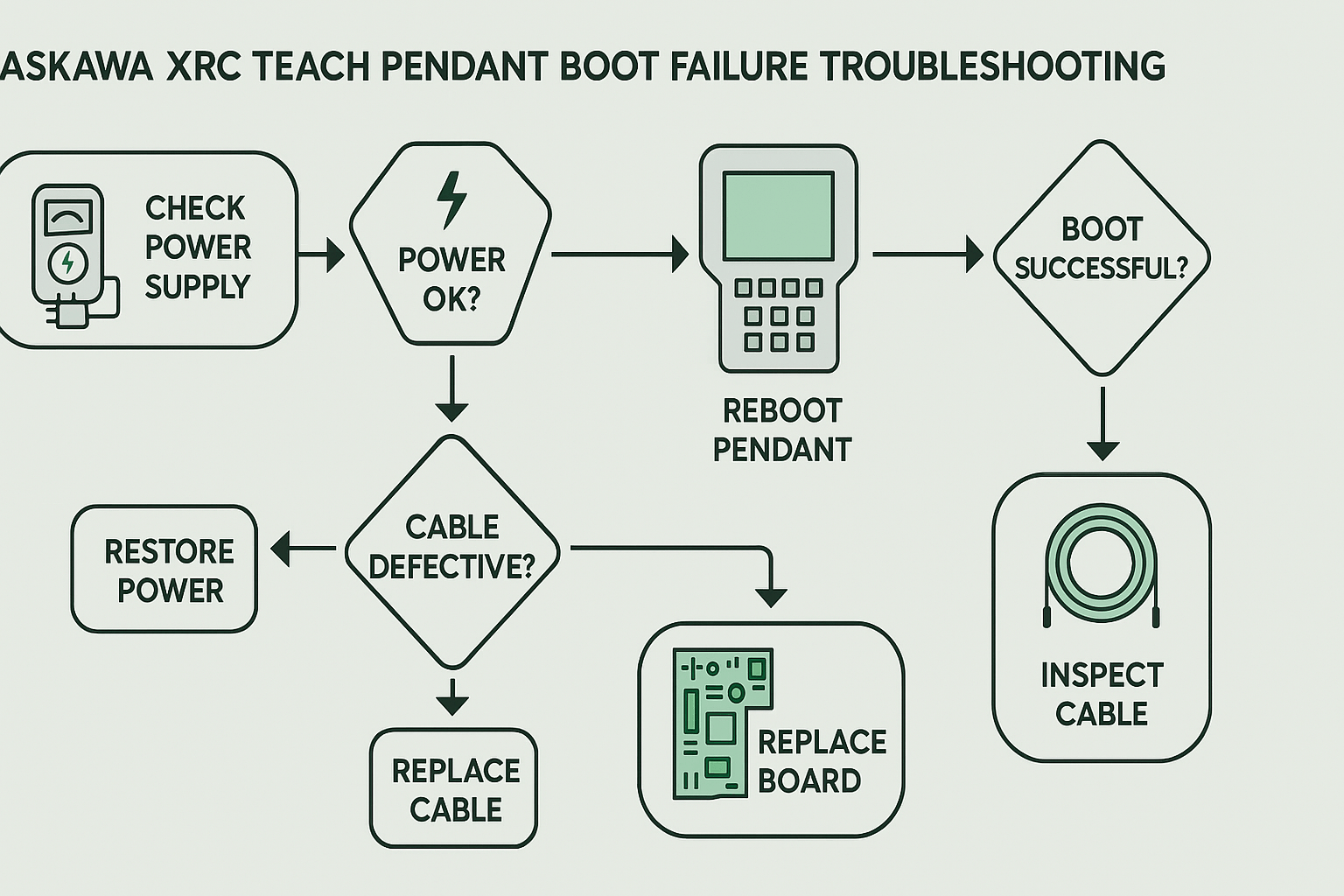

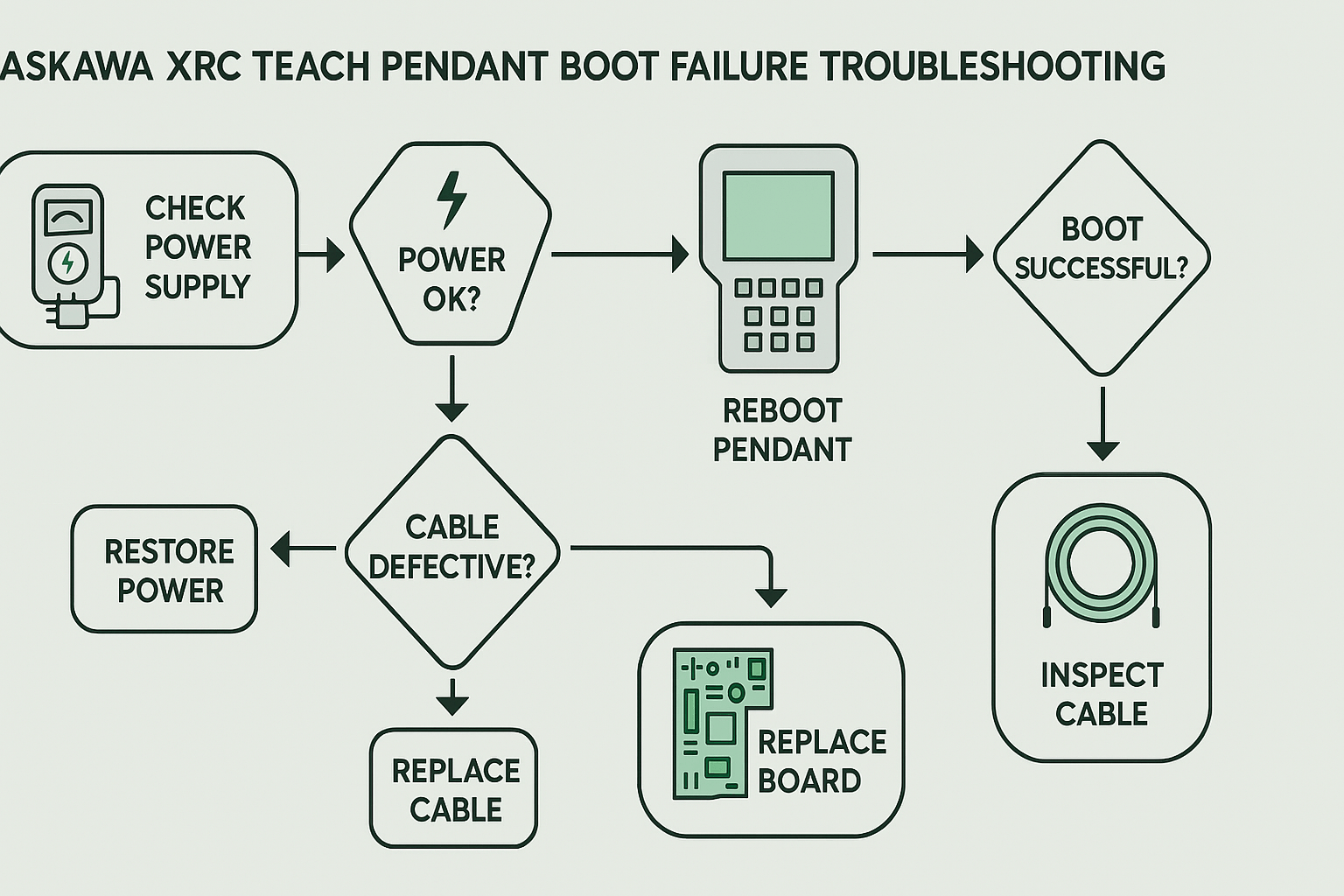

Step-by-Step Troubleshooting Guide for Yaskawa XRC Teach Pendant Boot Failures

Follow this workflow, adapted from Yaskawa's boot sequence in the XRC Instructions Manual and real-user fixes from Robot-Forum. Safety first: Lock-out/tag-out power and ensure no personnel in the robot envelope.

Step 1: Power Checks (Start Here, 70% of Cases)

- Verify 200-220V AC (±10%/-15%) at R-S-T terminals. Bypass transformers if using RPCs.

- Inspect CPS-150F indicators: Green = normal; red = +5V/+24V alarms. Check fuses FU1-6.

- Test 24VDC at CN03 pins 2-3 and comm at XCP CN02.

Step 2: Isolate Pendant vs. Controller

- Swap the Yaskawa XRC Teach Pendant and cable — common fix for “booting” loops.

Step 3: Safety Hardware Verification

- Confirm E-STOP and dead-man switch (mid-position for servo ON). Check playback panel wiring and pseudo input #8216.

Step 4: Board and Memory Diagnostics

- Re-seat XCP01, XCP02, and WRCA01 boards. Look for 4502 SL BOARD ERROR.

- Format memory cards to FAT16 (use Windows 98 VM); avoid >32MB sizes.

- For absolute data errors, calibrate home position.

Step 5: Advanced Fixes and When to Call Pros

- Fan/temp checks: Replace if 1200 HIGH TEMPERATURE triggers.

- If +5V persists, swap boards sequentially — our VICPAS stock includes refurbished XCP01 units with 1-year warranty.

- Never improvise firmware: Download only from official Motoman hub.

In a recent VICPAS case, a client resolved an XRC + SV3X +5V boot failure by replacing a single mismatched board, saving weeks of downtime.

Preventive Maintenance for Reliable Yaskawa XRC Teach Pendant Performance

- Battery Routine: Swap ER6VC3N every 2-3 years; monitor via 3014 alarms.

- Environmental Controls: Keep controllers in <40°C, low-humidity spaces.

- Regular Calibrations: Home position after any encoder/motor changes.

- Backup Everything: Use pendant's {DATA} → {BACKUP} for params and jobs.

At VICPAS HMI Parts Center, we offer customized Yaskawa XRC Teach Pendant maintenance kits, including batteries, cables, and housings with no MOQ. Our 20+ years in HMI parts ensure compatibility and rapid turnaround.

Ready to Fix Your Yaskawa XRC Teach Pendant?

Don't let boot failures or error codes slow your production. Contact VICPAS today — worldwide delivery, 12-month warranty, expert support.

Browse XRC Parts Now Get a Fast QuoteReferences & Official Sources

- Yaskawa XRC Instructions Manual (Official PDF)

- Robot-Forum: Motoman UP6 with XRC won't boot up

- Robot-Forum: XRC system booting issues

- Robot-Forum: XRC + SV3X +5V problem

- Motoman Official Product Documentation Hub

- XRC Alarm List (Mirror)

*This guide is for informational purposes; always consult Yaskawa manuals for your specific setup. VICPAS is not affiliated with Yaskawa but proudly supports their ecosystem.*